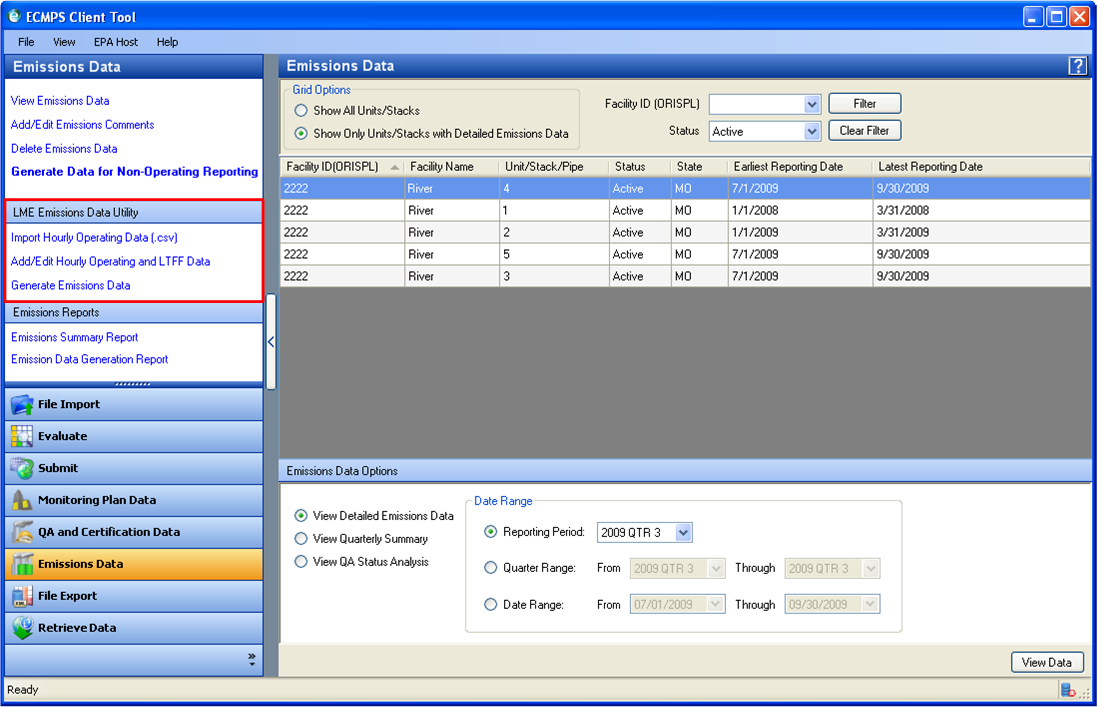

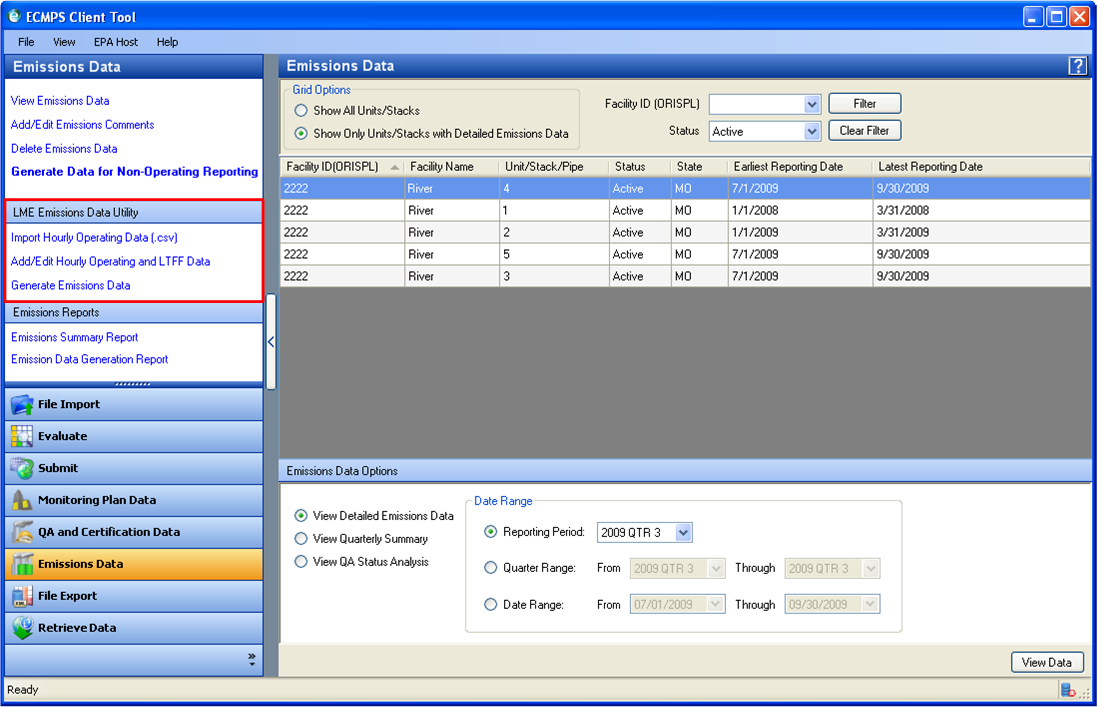

The Low Mass Emissions (LME ) Data Utility allows you to create quarterly emissions files for a monitoring configuration of one or more units qualifying as LME units under § 75.19. The lme emissions data utility panel is located in the Module Action Panel of the Emissions Data module, above the Emissions Reports panel (see image below). LME Specific Hourly Operating Data can be imported from a file, generated, or added manually through the Client Tool.

To import your LME Hourly Operating data, it must be in a comma separated value (.CSV) format. The file must contain a line per hour with the following data elements, in this order, separated by commas. If there is no value for a field, leave the field blank. Do not enter "0" (zero).

-- ORIS Code

-- Unit ID

-- Date (YYYYMMDD)

-- Hour (00-23)

-- Operating time (0.00 -1.00)

-- Load (integer)

-- Load Units of Measure Code (MW, KLBHR, MMBTUHR)

-- Fuel Codes of Fuels Combusted During Hour (individual fuel codes delimited by semi-colon)

-- Operating Condition Code (C, U, B, P, or blank)

-- MHHI Indicator (Y or blank)

Note 1: Each file should contain data for only one monitoring configuration and one reporting period.

Example #1: ORIS 1001, unit 1, May 22 1999, 2:00pm operating for a full hour combusting pipeline natural gas and diesel with controls operating, output of 35 MW

1001, 1, 19990522, 14, 1.00, 35, MW, PNG;DSL, C,,

Example # 2: ORIS 1001, unit 1, June 8, 1999, 3:00 am, non operating hour

1001, 1, 19990608, 3, 0.00,,,,,,

Note 2: There must be a comma following each data element (i.e., nine commas in each line) in order for ECMPS to import the .CSV file. This includes commas after each blank entry. ECMPS will not import a .CSV file created in Microsoft Excel if there are fewer than nine commas. To check the file, open the .CSV file in a text editing program such as Notepad and ensure that nine commas are displayed for each hourly record.

Note 3: The MHHI indicator should be set to Y only if:

1) The Monitoring Plan contains:

a) an active Heat Input Method record where the Method Code is LTFF (Long Term Fuel Flow) and the Substitute Data Code is MHHI and,

b) an active Default record where the Parameter Code is MHHI,

AND;

2) Substitute data (i.e., MHHI default) was used during the hour instead of an LTFF apportioned Heat Input value.

Otherwise, the MHHI element should be blank.

To import the LME Hourly Operating data file, click the import hourly operating data (.csv) link in the lme emissions data utility panel. Click the add file button in the lower right corner of the screen to select files to import. When the files to be imported are in the import queue, click the import button to start the import process. For each file in the import queue, checks will be run to validate the hourly operating data. The status of the import process for each file will be shown in the Status column of the grid. If there are any errors, the status will contain a link to view the error report.

Once you have imported the LME data into the Client Tool database, your hourly operating data will be available for editing. To edit the data, click the hourly operating and ltff data link in the lme emissions data utility panel. Select the LME monitoring configuration and reporting period that you want to modify. The location dropdown box in the upper section of the Working Panel contains all locations in the configuration. The locations are listed alphabetically by group. The group order is active/future stacks/pipes, active/future units, inactive stacks/pipes, and inactive units. If you select a unit, both the add/edit hourly operating data tab and the add/edit long term fuel flow data tab will be enabled. If you select a common pipe, only the add/edit long term fuel flow data tab will be enabled. If there are no LME data associated with the selected location and date range, the lme emissions data utility grid in the upper section of the Working Panel and the fields in the lower section of the screen will be empty. If there are LME data associated with the selected location and date range, you can select a record in the upper grid and edit the fields in the lower section of the screen. To create a new Hourly Operating Data Record, click the add button.

To create new hourly operating data, enter the appropriate hourly operating information in the lower section of the Working Panel. Click the expand button to increase the size of the lower section of the Working Panel. The collapse button will return the lower section to its normal size in the Working Panel.

The following LME specific fields can be added or edited:

-- Date (date within the reporting period)

-- Hour (integer between zero and 23)

-- Operating time (two decimal-place number between 0.00 and 1.00)

-- Load (integer greater than or equal to zero)

-- Load Units of Measure Code (MW, KLBHR, MMBTUHR)

-- Fuel Codes of Fuels Combusted during Hour (any FUEL_CD in the FUEL CODE table where FUEL_GROUP is "GAS" or "OIL"; list is saved as semicolon-delimited string)

-- Operating Condition Code (C, U, B, P, or blank)

-- MHHI Indicator (Y or blank)

Note 1: The MHHI indicator should be set to Y only if:

1) The Monitoring Plan contains:

a) an active Heat Input Method record where the Method Code is LTFF (Long Term Fuel Flow) and the Substitute Data Code is MHHI

and,

b) an active Default record where the Parameter Code is MHHI,

AND;

2) Substitute data (i.e., MHHI default) was used during the hour instead of an LTFF apportioned Heat Input value.

Otherwise, the MHHI element should be blank.

Note 2: Total Heat Input can be viewed but cannot be edited. It will be calculated during the Generate Emissions Data process.

Click the save changes button to save the data or the cancel changes button to cancel the changes to the hourly operating data. The Client Tool will prevent you from saving invalid hourly operating data. When you attempt to save hourly operating data, the Client Tool will perform data checks to validate the data. If there are data errors, a pop-up screen will display the error messages. If there are any fatal errors, the data cannot be saved. To delete an hourly operating data record, clicking the remove link for the record in the upper grid.

You can generate default hourly operating data for a specified range of date and hours. When the HOURLY OPERATING DATA tab is active, click the GENERATE HOURLY OPERATING DATA button. A new window will pop up. Select the hours for which you would like to generate data using the START DATE and END DATE dropdown menus. Under the OPTIONS menu, the default setting is REPLACE EXISTING HOURS. Leaving this box checked will cause any existing data for this configuration to be overwritten. If you do not want to overwrite existing data, but instead would like to fill in only those hours for which data has not been entered, choose the insert MISSING HOURS radio button. Enter the Operating Time, Load, Load Units of Measure, Fuel Code(s), Operating Condition Code, and MHHI Indicator in the appropriate fields below and click SAVE.

To export hourly operating data for all locations in the configuration to a comma-delimited text (CSV) file, click the export hourly operating data for all locations button.

To add or edit long term fuel flow data, click the long term fuel flow data tab. If there are no Long Term Fuel Flow records associated with the selected location in the dropdown box, the grid in the upper section of the Working Panel will be empty. If there are Long Term Fuel Flow data associated with the selected location and data range, you can select a record in the upper grid and edit the fields in the lower section of the screen. To create a new Long Term Fuel Flow data record, click the add button.

To create new long term fuel flow data, enter the appropriate Long Term Fuel Flow information in the lower section of the Working Panel. Click the expand button to increase the size of the lower section of the Working Panel. The collapse button will return the lower section to its normal size in the Working Panel.

The following Long Term Fuel Flow specific fields can be added or edited:

-- Long Term Fuel Flow System ID (MonitoringSystemID of any LTOL and LTGS system at the location)

-- Fuel Flow Period (A, MJ, or blank)

-- Fuel Flow (integer greater than zero and less than or equal to 9,999,999,999)

-- Fuel Flow Units Of Measure (LB, GAL, SCF)

-- GCV (one decimal-place number greater than zero and less than or equal to 99,999,999.99)

-- GCV Units Of Measure (BTULB, BTUGAL, BTUSCF)

Click the save changes button to save the data or the cancel changes button to cancel the changes to the long term fuel flow data. The Client Tool will prevent you from saving invalid Long Term Fuel Flow data. When you attempt to save long term fuel flow data, the Client Tool will perform data checks to validate the data. If there are data errors, a pop-up screen will display the error messages. If there are any fatal errors, the data cannot be saved. To delete a Long Term Fuel Flow data record, click the remove link for the record in the upper grid.

To generate LME emissions data, click the generate emissions data link in the lme emissions data utility panel. A grid will appear on the Working Panel with one row for each monitoring configuration that contains an LME unit and has hourly operating data in the Client Tool database. You can filter data in the grid by Facility ID (ORISPL) or by MP Status by using the filter and clear filter button. After selecting the desired configuration, select a reporting period in the dropdown box at the bottom of the screen. The box will contain all LME-eligible reporting periods for which an Emissions Evaluation record exists in descending order. After selecting the configuration and reporting period, click the generate button to generate the emissions data.

The Client Tool will perform data checks on the hourly operating data, long term fuel flow data, and monitoring plan data to assure that the emissions data can be generated successfully. If there are no fatal or critical errors, the check engine will delete all Derived Hourly Value and Summary Value records for the configuration and reporting period prior to storing the data in the Client Tool database. However, if there are fatal or critical errors, no emissions data will be generated.

After the data checking process is completed, if there are no errors, the Emissions Data module will display the emissions data for the selected configuration and reporting period. If there are errors in the generation of emissions data, the Client Tool will remain in the LME Emissions Data Utility and will display the emission data generation report.

Tutorials: To watch various tutorials that briefly explain some of the main aspects of the ECMPS Client Tool, visit the ECMPS Support website.

Feedback: Did this help topic answer your question? Can it be improved? Click here to let us know.